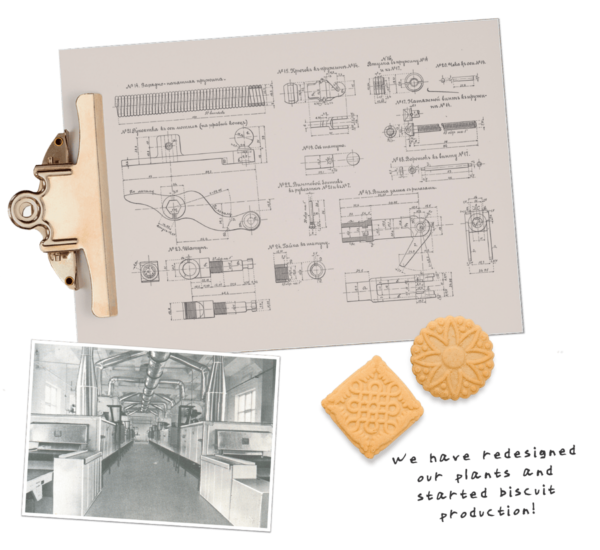

“Domaćica” is the first product that was created by the end of 90’s on the machines that we created independently in our factory at the time.

At first, those were crispy biscuits covered with cocoa topping on one, flat side. However, as production, at first, was conducted on the improvised machines, some of the biscuits would turn over on a flat side, along a conveyor belt and some of them on a rough side.

For that reason, all the time during production, 5 workers stood beside a conveyor belt, and once baking was over they turned the biscuits to a correct, flat side, thus preparing them for topping.

“Domaćica” had achieved great market success, the production was modernised, and the process itself was automated.

Besides the first, genuine “Domaćica” that was made in Kikinda, the assortment was expanded with new products – Tart and Flower.